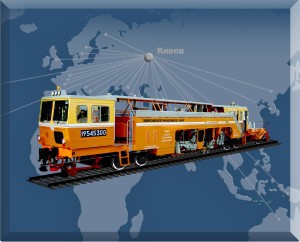

Liner-tamper-straightening machine ВПРС-03 is destined for railway track alignment in longitudinal and cross profiles and in projection and also for a ballast compacting under the sleepers and at the flanks of the sleepers, under the bars of the turnouts and the frogs.

The machine is applied in building of new, repairs and current maintenance of the active railways having track 1435 and 1520 mm with the rails up to P65 inclusively with the wooden and ferro-concrete sleepers on the ballasts of various types. ВПРС-03 is a universal track machine of a cyclic action executing simultaneous or independent alignment, straightening and tamping of a railway track in semi-automatic or manual mode both on the main and station tracks and on the turnouts.

The machine is equipped with a remote unit for raising a third rail providing work on the heavy turnouts with the ferro-concrete

bars. This unit allows to execute raising of a third rail and partial tamping of a long bar in a 3rd point for its fixing. The two-sleepers tamping blocks are installed on the machine, which execute tamping of one sleeper from two sides and two adjacent sleepers from one side. Automated oiling system of the most loaded elements of the tamping blocks (total 40 lubrication points) of “Lincoln” Co. (Germany) allows to expel technological brakes while the machine is working.

A transmission of the machine is made on a hydrodynamic transmission base. Control of the machine aligning systems is exercised from a microprocessor system. A board computer equipped with a keyboard for entry of an operative information is destined for: information collection and storage about track condition before and after alignment and about track design parameters; execution of operations calculation and control signals shaping of track alignment system; providing a dialog mode with a user.

ВПРС-03 is equipped with a microprocessor control system of technological cycle «Спрут-4006» realizing three machine

working modes:

working – executes and controls desired work actigram of the machine;

adjusting – is for adjusting the work parameters, scaling the transducers and zeros affixment;

test-diagnostic – allows to detect on-the-fly and isolate a failure.

A rear cab of ВПРС-03 is equipped with an in-house mini-block consisting of: wardrobe, wash-stand, thermo-electric refrigerator, seats with a table which, if necessary, are transformed into a place for rest. A working cab is equipped with a conditioner and video surveillance system consisting of four video cameras transmitting the pictures from the most difficult for survey working zones and a space before the machine on motion to two LCD.

ВПРС-03 is able to move on its own on the main tracks to a working place owing to high transport speed, available radio, system of traffic safety (installed at a customer’s request), automated system of fire detection and extinguishing in a power plant.

Climatic version type У1 ГОСТ 15150, but for work at an environment temperature from -10°C up to +40°C when a ballast is not regelated.

The following versions of the machine power plant are pissible:

diesel ЯМЗ-238Д with hydro-transmission БЕЛАЗ (ВПРС-03);

diesel “Cummins” (USA) with hydro-transmission “Voith” (ВПРС-03.2).

Main technical characteristics*

|

Denomination of parameter |

Value of parameter |

|

Production capacity: when aligning and tamping a track, sleepers/hour, up to when tamping the turnouts, turnouts/hour, up to |

1200 1,2 |

|

Accuracy of alignment of a track: of longitudinal profile on a base of 2,5 m, ‰ (no more than) track twist (difference in the rails position on the level on the length of 1 m), mm, (no more than) in projection – difference of two adjacent bending deflections measured in the center of 20-m chord on a circular curve 5 m further on, mm (no more than) |

1,0 ±2,0 ±2,0 |

|

Maximum value of track raising, mm |

100 |

|

Maximum value of gage adjustment, mm |

100 |

|

Maximum surmountable track slope, ‰ (grades) |

20,0(1,14) |

|

Maximum self-propelled transport moving speed, km/h |

80 |

|

Minimum radius of passed curvatures, m: when the executing devices are in a transport position when in a working position |

80 120 |

|

Overall dimensions, mm: length height with aerial width |

23 500 4 150 3 050 |

|

Weight in equipped condition, t |

60 |

|

Control crew, pers. |

4 |

1st May Kirovsky Mashzavod

*To provide technical characteristics required to the machine, the elements of a permanent way crest structure (rails, sleepers, binds, ballast, profile,etc.) must meet the requirements of the normative-technical documents valid relatively to the railways of a customer.

The Enterprise reserves the right to bring alteration into kitting-up and technical characteristics of produced equipment. Technical characteristics and possible kitting-up shall be necessary specified in a process of preparing of a request.

© Roctok LLC group of companies, 2026

© Roctok LLC group of companies, 2026