Purpose, application domain and parameters of machine mod. 6963-022 for machining a side frame

Machine mod 6963-022 is destined for machining a “side frame” detail. It provides machining both new cast workpiece and a detail restored by weld deposition.

The machine provides machining the support and side surfaces of an axle box openings.

Table 1. Technical characteristic of machine mod. 6963-022

|

Denomination of parameters |

Value |

|

1 |

2 |

|

Travels, mm - Leg (X axis) - Stock (Y axis) - Sliding block (Z axis) Z) |

2100 550 400 |

|

Main drive power (S1/S6), kW (S1/S6), кВт |

11/15 |

|

Spindle rotation frequency, rpm |

20 – 1000 |

|

Sliding block spindle taper |

ISO 50 |

|

Value of working feeds at all the 0,5 - 5000 axes, mm/min. |

0,5 – 5000 |

|

Value of rapid travels al all the 15000 axes, mm/min. |

15000 |

|

Overall dimensions of the machine, mm: - length - height - width - width with attached equipment |

4900 2400 2500 3100 |

|

Weight of machine, kg |

8300 |

Composition and design of machine 6963-02X

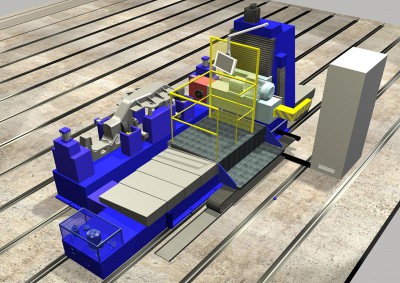

The machine consists of three-coordinate milling module and device for clamping the machined detail.

Milling module consists of the bed where the leg, having possibility for moving along the bed (X axis), is located on. The leg wears the milling stock consisting of the vertical movable sledge (Y axis) Y) and horizontal sliding block (Z axis). Z).

4-spindle milling head has been installed on the flank of sliding block.

Feed drives at all the coordinates have been made on the frequency controlled motors with the ball-screw drive at every segment.

Control system provides work of the machine in independent mode and in automatic line mode.

Diagnostic system gives working availability estimation and identifies failures in the most important systems and mechanisms of the machine, systems of hydraulic equipment, oiling, electric equipment, drives of main movement and feed, ensures automatic switching situation occurs, off the machine when emergency possibility for quick detecting the breakage.

Design features among the machines are determined by spindle groups, unification between them is up to 80%, and the devices.

Individual device is delivered for each processed detail, for its stationing and clamping. All the devices are hydroficated and provide possibility for loading and unloading the processed details both by automatic manipulator and in manual mode.

Main component parts:

· Ball-screw pairs of feed drives – “Micron” Co., Ukraine or TNK, Japan.

· Feed drives – “OMRON” Co. «OMRON», Japan

· Control system programmable controller - “OMRON” Co., «OMRON», Japan

· Inverter (frequency converter) - “OMRON” Co., «OMRON»,Japan

· Control cabinet casing – “RITTAL” Co., «RITTAL», Germany

· Casing of control board with suspension - “RITTAL” Co., «RITTAL», Germany elements

· Panel of control board with color display - “OMRON” Co., «OMRON», Japan

· Hydraulic cylinders – import (Poland, Germany)

· Pneumo-hydro-accumulator – import (Poland, Germany, Italy),

· Transducers of travels reading – СКБ ИС, Saint-Petersburg

Technical requirements

The machines have been certified in the ГОСТ-Р system.

They meet the requirements:

ГОСТ 7599 “Metal Cutting Machines. General Technical Conditions”, ГОСТ 12.2.009 “Metal Cutting Machines. General Safety Requirements”;

ГОСТ 12.2.003 ССБТ “Production Equipment. General Safety Requirements”;

ГОСТ Р МЭК 60204.1 ССБТ “Safety of machines. Electric equipment of machines and mechanisms. Part 1.I. General Requirements”;

ГОСТ 12.2.107 ССБТ “Noise. Metal Cutting Machines. Admissible Noise Characteristics”;

ГОСТ 12.2.049 “Production Equipment. General Ergonomic Requirements”.

© Roctok LLC group of companies, 2026

© Roctok LLC group of companies, 2026