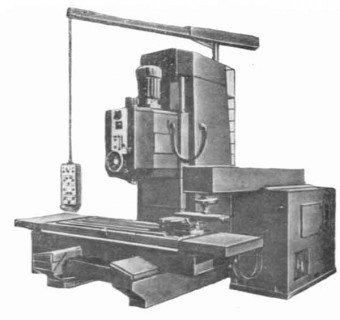

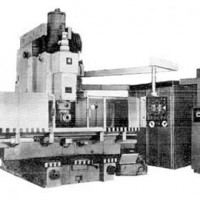

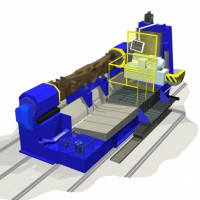

A machine is destined for machining the details from non-ferrous and ferrous metals, including extra-high strong steels, with fast-cutting and hardalloyed tools of different types. Execution of simple boring and drilling works is possible with this machine by vertical feed of a spindle stock.

|

Parameters |

Values |

|

Diameters of machined wheels on rolling circle, mm |

860 … 964 |

|

Diameters of machined hub holes, mm 1st range 2nd range |

182 … 198 204 … 214 |

|

Width of wheel hub, mm |

190 +10,195 +10 |

|

Spindle taper |

External taper 7:24 |

|

Travel values, mm: axial of sliding block radial shifting of a tool when spindle inclination |

300 +/-16 |

|

Spindle rotation frequency, rpm |

50 … 400 |

|

Feed speeds, mm/min. axial of sliding block radial of spindle |

1 ... 7000 0.25 ... 250 |

|

Spindle drive motor power, kW |

30(S6) |

|

Total power of installed motors, kW |

35 |

|

Discreteness of travels reading, mm axial of sliding block radial of spindle |

0.010 0.001 |

|

Precision of travels, mm axial of sliding block radial of spindle |

0.030 +/-0.004 |

|

Precision of shape of machined holes, mm: circularity deviation longitudinal section profile deviation – taper, mm (bigger diameter of a wheel inside) |

no more than 0.025 no more than 0.050 |

|

Hub alignment relative to a wheel rolling surface after machining, mm |

no more than 0,2 |

|

Hub hole axis perpendicularity to a crown flank surface from a wheel flange side after machining, mm |

no more than 0,2 per 1 м. |

|

Square occupied by machine (with attached equipment), mm (length x width x height) |

2460 х 2850 х 2100 |

|

Weight, kg |

7500 |

© Roctok LLC group of companies, 2026

© Roctok LLC group of companies, 2026