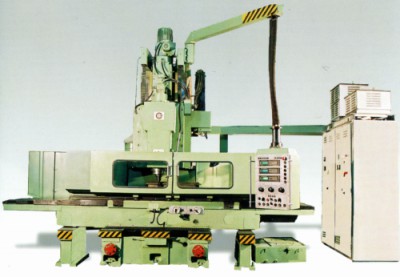

Machine mod. 65A60Ф1 (Ф13) is destined for high production milling, drilling, countersinking, reaming and boring the details from iron, steel and non-ferrous metals. Machining the raw and hardened details is executed with the machine using the modern tools having the cutters from el-boron, ultrastrong composition materials from cermet. A system of adaptive control provides machining the details in optimal cutting modes with automatic feed control subject to cut overdimension and a tool wear.

Technical characteristics

|

2000х630 |

|

|

Extreme distance from spindle flank to table working surface, mm |

|

| - maximum |

900 |

|

- minimum |

125 |

|

Maximum travel,mm |

|

|

- in longitudinal direction of table (X axis) |

1600 |

|

- in cross direction of table (Y axis) |

630 |

|

- in vertical direction of stock (Z axis) |

775 |

|

Spindle end taper |

50 |

|

Limits of spindle rotation frequency, min.-1 |

5...2000 |

|

Main drive motor nominal power, kW |

20 |

|

Maximum weight of a detail installable on the table of machine (with a device), kg |

3000 |

|

Overall dimensions of machine together with separately located units and electric equipmens, mm, no more than |

|

| - length |

6185 |

| - width |

3825 |

|

- height |

4100 |

|

Weight of machine (with separately located units and electric equipmens), kg |

16130 |

© Roctok LLC group of companies, 2026

© Roctok LLC group of companies, 2026