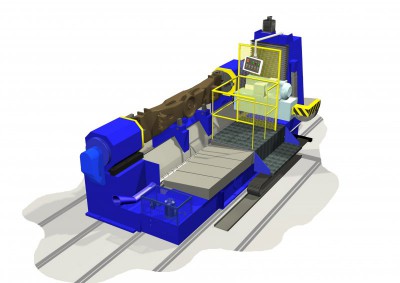

Destination and domain of application of machine model 6963-01

Machine model 6963-01 is destined for complex machining a “bogie bolster” detail. It provides machining both new cast work-piece and a detail restored by weld deposition. The machine executes milling operations of a center bowl (including outer surface), inclined surfaces, bearers, boring a pivot hole and drilling the holes Ø23 mm.

Main design decisions of the machine:

- united design base having unification up to 80%;

- program control (programmable controller);

- input of the machining parameters for a concrete detail can be executed:

- in a manual mode;

- by an information reading from the bar codes received with a measurement inspection machine;

- from electronic net.

- parameters of the machine are meant for application of a high production tool having faceted hardalloyed nonresharpened plates;

- hydroficated gadget for stationing and clamping a detail.

Technical requirements

The machines have been certified in the ГОСТ-Р system.

They meet the requirements:

ГОСТ 7599 “Metal Cutting Machines. General Technical Conditions”, ГОСТ 12.2.009 “Metal Cutting Machines. General Safety Requirements”;

ГОСТ 12.2.003 ССБТ “Production Equipment. General Safety Requirements”;

ГОСТ Р МЭК 60204.1 ССБТ “Safety of machines. Electric equipment of machines and mechanisms. Part 1. General Requirements”;

ГОСТ 12.2.107 ССБТ “Noise. Metal Cutting Machines. Admissible Noise Characteristics”;

ГОСТ 12.2.049 “Production Equipment. General Ergonomic Requirements”.

Precision standards of the machine provide execution of the drawings of machined details requirements on accuracy of the dimensions and shape, accuracy of the surfaces position and quality of the surfaces (asperity).

Climatic version of the machine УХЛ 4.1 under ГОСТ 15150.

Technical factors of the machine reflecting technological and exploitation ability are shown in table 1.

Table 1. Technical characteristic of machine mod. 6963-01

|

Parameters denomination |

Value |

|

1 |

2 |

|

Travels, mm - leg (X axis) - stock (Y axis) - sliding block (Z axis) |

2100 550 400 |

|

Main drive power (S1/S6), kW |

11/15 |

|

Spindle rotation frequency, rpm |

20 – 1000 |

|

Sliding block spindle taper |

ISO 50 |

|

Value of working feeds at all the axes, mm/min |

0,5 – 5000 |

| Value of rapid travels at all the axes, mm/min |

10000 |

|

Overall dimensions of machine, mm: - length - height - width - width with attached equipment |

4900 2400 2400 3000 |

|

Weight of machine, kg |

9000 |

Composition and design of machine 6963-01

The machine consists of a three-coordinates module and a gadget for clamping a machined detail.

Milling module consists of a bed where is located a leg able to move along the bed (X axis). The leg bears a milling stock consisting of a vertical movable sledge (Y axis) and a horizontal sliding block (Z axis).

Feed drives at all the coordinates are equipped with the frequency- controlled motors having ball-screw gears at every segment.

Control system provides work of the machine in an off-line and in in-line modes.

A diagnosis system gives estimation of a working capacity and defines the faults of the most important systems and mechanisms of the machine, systems of hydraulic equipment, oiling, electric equipment, main movement and feed drives, automatic switching off the machine in case of emergency situation, possibility of quick detection of a malfunction.

Design differences between the machines are specified by the spindle groups, unification between them is up to 80%, and by the gadgets.

Special gadget is delivered for each machined detail for its stationing and clamping. All the gadgets are hydroficated and provide possibility for loading and unloading the machined details both by an automatic manipulator and in a manual mode.

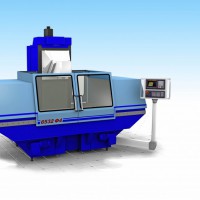

Destination and application domain of machine mod. 6963-02X

Machine mod. 6963-02X is destined for a “side frame” detail machining. It provides machining both new cast work-piece and a detail restored by weld deposition.

Machines mod. 6963-02X execute the following milling operations:

- machine mod. 6963-022 provides machining a support and side surfaces of the axle box openings;

- machine mod. 6963-024 provides machining the outer flanks of an axle box side surfaces;

- machine mod. 6963-021/23 provides complex machining the surfaces for friction plates in a bolster opening – milling and drilling.

Table 1. Technical characteristic of machine mod. 6963-02X

|

Parameters denomination |

Value |

|

1 |

2 |

|

Travels, mm - leg (X axis) - stock (Y axis) - sliding block (Z axis) |

2200 600 450 |

|

Main drive power (S1/S6), kW |

11/15 |

|

Spindle rotation frequency, rpm |

20 – 1000 |

|

Sliding block spindle taper |

ISO 50 |

|

Value of working feeds at all the axes, mm/min |

0,5 – 5000 |

|

Value of rapid travels at all the axes, mm/min |

15000 |

|

Overall dimensions of machine, mm: - length - width - height |

3400 1850 2100 |

|

Weight of machine, kg |

6000 |

Composition and design of machine mod. 6963-02X

The machine consists of a three-coordinates module and a gadget for clamping a machined detail.

Milling module consists of a bed where is located a leg able to move along the bed (X axis). The leg bears a milling stock consisting of a vertical movable sledge (Y axis) and a horizontal sliding block (Z axis).

Feed drives at all the coordinates are equipped with the frequency-controlled motors having ball-screw gears at every segment.

Control system provides work of the machine in an off-line and in in-line modes.

A diagnosis system gives estimation of a working capacity and defines the faults of the most important systems and mechanisms of the machine, systems of hydraulic equipment, oiling, electric equipment, main movement and feed drives, automatic switching off the machine in case of emergency situation, possibility of quick detection of a malfunction.

Design differences between the machines are specified by the spindle groups, unification between them is up to 80%, and by the gadgets.

Special gadget is delivered for each machined detail for its stationing and clamping. All the gadgets are hydroficated and provide possibility for loading and unloading the machined details both by an automatic manipulator and in a manual mode.

© Roctok LLC group of companies, 2026

© Roctok LLC group of companies, 2026