DESTINATION

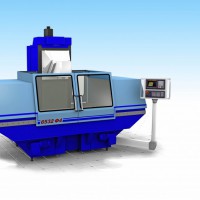

Special milling-boring machine with CNC УФ5527М is destined for complex machining a bogie bolster and a side frame in the bogies of freight railway cars renewal process. Machining is executed after reconditioning of the worn surfaces by electric weld deposition method. The machine provides simultaneous processing the surfaces of center bowl and sequential machining the planes of sliding blocks and the inclined surfaces of bogie bolster ( turn of a bogie is mechanized).

Design of a gadget has been made so that in it is possible, with a minor readjusting, to install and to machine in turn a bogie bolster and a side frame. When a couple of machines are delivered, each can be kitted with a gadget adjusted for machining a bogie bolster or a side frame. According to an order the machines are equipped with special cutting and auxiliary tools. Set of 4 designations of milling cutters and the holders provides full machining a bogie bolster and a side frame in a renewal process.

DESIGN FEATURES

A base machine is vertical milling machine with cross table mod. 6580Ф4 with CNC from “Siemens” Co. kitted with a gadget for the work pieces installation and clamping. The machine provides complex machining a detail at one installation in the gadget when the base characteristics of the machine are saved.

Clamping a tool in a spindle is mechanized. Clamping the work pieces, their turn are executed by fast mechanisms with manual drive.

When the gadget is removed from the table the machine can process any detail installed on its table. Application of CNC system with the machine gives 30% increase in machining precision and labor production capacity in comparison with a machine mod. УФ5527 without CNC.

TECHNICAL DATA

Technical characteristic (main parameters and dimensions)

Precision class H under ГОСТ 8-82

|

Dimensions of a table working surface, mm: length Quantity of T-shaped chases Distance between the chases, mm Width of a chase, mm Distance from a spindle flank to a table working minimum Spindle end under ГОСТ 24644-81 Angle of a milling stock turn, grade Distance from a spindle axis to the leg guides, mm Maximum coordinate travel, mm table X slide Y stock Z Limits of feeds, mm/min. table X slide Y stock Z Rapid move, mm/min table X slide Y stock Z Limits of a spindle speeds, rpm Quantity of a spindle speed stages Move of a barrel, mm Travel of a barrel per a flywheel turn, mm Maximum weight of a machined detail, kg Overall dimensions of machine, mm: length width height Total weight of machine, kg: with electric equipment without electric equipment

|

1600 800 5 100 28(28H9 middle chase)

900 160 50 +30 grades 800

2085 750 610

2…3000 2…3000 2…2000

4000 4000 2000 25…1250 18 125 2 2000

3920 3995 4055

15100 14100

|

Technical characteristic of electric equipment

|

Quantity of motors on a machine Main movement motor type Power, kW Speed of rotation, rpm Type of motors of table, milling stock, slide drive Nominal power, kW Speed of rotation, rpm (nominal) Type of oiling pump motor Power, kW Speed of rotation, rpm Type of cooling pump motor Power, kW Speed of rotation, rpm Type of CNC unit Type of reading transducer Discreteness of procesing |

7 4А160 S 4У3 15 1500 ПБВ132LЕУ3 3 600 4АА63А4У3 0,27 1480 АОЛ21-2СПУЗ 0,12 2800 Sinumerik 802D Photo-electric ЛИР158А 0,01 |

2.2. Technical characteristic of oiling system

|

Mark of oil Type of gear pump Capacity, l/min. Type of reversible pump Capacity, l/min. Type of intake filter Filtration rating, mm Type of pressure filter Filtration rating, mm Type of a stock filter Filtration rating, mm Type of pressure hydraulic valve |

И-30 ГОСТ 20799-88 БГ11-11А УХЛ4 8 С12-4М-3, 2У4 5 20-160 ОСТ2 С41-2-80 0,16 1ФГМ16-10К УХЛ4 0,12 СУ41-11 0,224 Г54-32М УХЛ4 |

© Roctok LLC group of companies, 2026

© Roctok LLC group of companies, 2026